Key Takeaways:

- Enhanced Operational Efficiency: Carton flow racks automate stock rotation and streamline the picking process, significantly increasing warehouse productivity. Enhance your warehouse with Space Maker Designs. Discover how our Pallet Flow Rack solutions can streamline your operations.

- Improved Space Utilization: By optimizing vertical space and reducing aisle width, these racks allow for a greater volume of inventory within the same footprint, enhancing storage capacity.

- Versatility and Scalability: With options for customization and integration with automated systems, carton flow racks offer flexible solutions adaptable to varying business needs and scalable for future growth.

In the logistics and warehouse management sector, efficiency is crucial for competitiveness and customer satisfaction. Carton flow racks, a storage solution that uses gravity to automate stock rotation and improve access to items, significantly enhance productivity and space utilization. This article explores how carton flow racks streamline pick and pack processes, underscoring their importance for businesses looking to boost operational efficiency.

Transform your storage strategy with Space Maker Designs. Pallet Flow Racks offer the efficiency and space savings you need.

Transform your storage strategy with Space Maker Designs. Pallet Flow Racks offer the efficiency and space savings you need.

Elevate Your Warehouse With Space Maker Designs

Discover How to Transform Your Storage and Efficiency

- Boost Your Efficiency: Discover storage solutions that enhance your operation's productivity and streamline processes.

- Optimize Your Space: Learn how to make the most of your warehouse layout, increasing storage capacity and accessibility.

- Adapt and Grow: Tailor your storage solutions to meet the evolving needs of your business, ensuring scalability and flexibility.

Understanding Carton Flow Racks

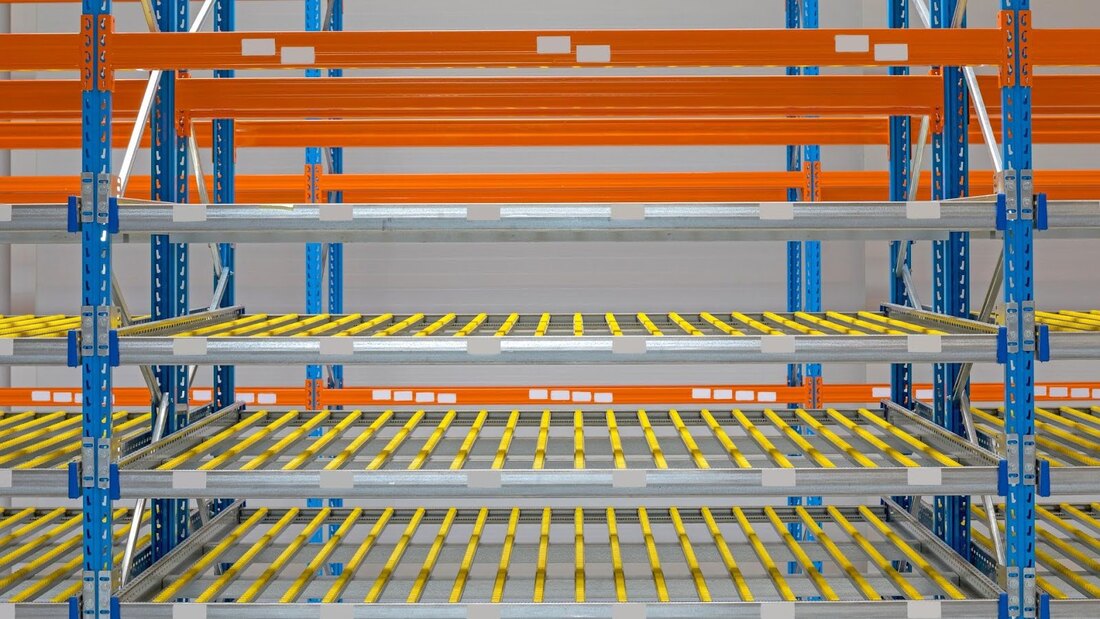

Carton flow racks use gravity to move products toward the pick-up area, reducing manual handling. This system is suitable for high-volume picking and FIFO inventory management, making it ideal for handling perishable goods. They enhance warehouse efficiency by automating stock rotation. Carton flow racks are configured with inclined shelves and rollers to facilitate the easy movement of goods. This storage solution is essential for warehouses aiming to improve operational efficiency.

Benefits Of Implementing Carton Flow Racks

Improved Space Utilization

Carton flow racks optimize the use of vertical space and reduce the need for wide aisles. This efficient spatial arrangement allows warehouses to store more products in the same footprint. By organizing items vertically, these racks free up floor space for other operations. The compact design also enables quick access to stored items, further enhancing space efficiency. Businesses benefit from decreased storage costs and increased inventory capacity.

Save space and improve flow in your warehouse with Space Maker Designs. Our Pallet Flow Racks are designed for your success.

Save space and improve flow in your warehouse with Space Maker Designs. Our Pallet Flow Racks are designed for your success.

Enhanced Picking Efficiency

With carton flow racks, items are automatically moved to the picking position, minimizing travel time for workers. This system streamlines the picking process, allowing for faster order fulfillment. Reducing the distance that workers travel, it also lowers the risk of errors during picking. The efficiency gains translate into the ability to handle more orders with fewer resources. Ultimately, this leads to higher productivity and customer satisfaction.

Reduced Worker Fatigue

Carton flow racks minimize the need for manual lifting and carrying, reducing physical strain on workers. This ergonomic solution contributes to a safer work environment and lowers the risk of injuries. By lessening worker fatigue, it also improves focus and efficiency among staff. A healthier workplace environment leads to better morale and reduced absenteeism. These factors combine to sustain high levels of productivity and operational continuity.

Increased Inventory Management Accuracy

This storage solution supports FIFO management, ensuring older stock is used first. Carton flow racks simplify stock rotation, minimizing waste from expired or outdated products. Accurate inventory management is easier to achieve, helping businesses avoid stockouts and overstocking. The system allows for real-time inventory tracking, facilitating better decision-making. Enhanced accuracy in inventory management leads to improved order accuracy and customer satisfaction.

How Do Carton Flow Racks Optimize Pick And Pack Processes?

Seamless First-In, First-Out (FIFO) Inventory Management

Carton flow racks naturally enforce FIFO inventory practices, essential for managing perishables. This ensures products are used in the order they are received, reducing spoilage. FIFO management also simplifies inventory tracking and forecasting. By automatically organizing stock, these racks minimize the labor involved in stock rotation. The result is a more efficient operation, with reduced waste and improved product quality.

Integration With Other Storage Solutions

These racks can be combined with other storage systems for a comprehensive solution. Integration allows for a tailored approach to storage, accommodating different product types and sizes. This adaptability improves overall warehouse efficiency and organization. By harmonizing different storage solutions, warehouses can optimize workflow and space usage. Integration also facilitates scalability, allowing operations to grow without significant reconfiguration.

Customization Options For Various Industries

Carton flow racks offer various customization options to meet specific operational needs. Adjustable shelves and rollers can accommodate different product weights and sizes. Customization ensures that the storage system aligns with the unique requirements of each industry. From retail to manufacturing, these racks can be tailored to enhance operational efficiency. The ability to customize these systems supports long-term operational goals and adaptations.

Key Considerations When Choosing Carton Flow Racks

Assessing Your Needs

Evaluating your current and anticipated storage needs is crucial before selecting a carton flow rack system. Consider product dimensions, weight, and turnover to identify the most suitable system. This initial assessment ensures that the chosen solution will adequately support your operation's efficiency and growth. Understanding your requirements can help avoid over- or under-investment in your storage infrastructure. A precise needs assessment lays the foundation for a successful implementation.

Capacity And Durability

Selecting a system with appropriate weight capacity and durability is essential. The chosen racks must withstand the daily demands of your operation without frequent maintenance. Durable systems offer a better return on investment by minimizing downtime and repair costs. Ensuring that the racks can support your inventory prevents safety hazards and product damage. Investing in high-quality materials and construction pays off in long-term reliability and safety.

Space And Layout Considerations

The design of your warehouse space significantly influences the effectiveness of carton flow racks. Optimal layout planning maximizes storage density and operational flow. Considerations include aisle spacing, accessibility, and integration with existing systems. Professional guidance can help design a layout that meets safety standards and operational efficiency goals. Tailoring the system to your space ensures a smooth implementation and operation.

Installation And Setup Of Carton Flow Racks

Planning And Design

The installation process begins with careful planning and design. This stage involves understanding the warehouse’s layout to determine the best placement for the racks. Effective design maximizes space utilization and operational efficiency. Collaboration with a storage solutions expert can ensure that your system meets both current and future needs. Proper planning and design are crucial for a successful carton flow rack installation.

Professional Installation

Professional installation is recommended to ensure safety and functionality. Experienced installers can accurately assemble the system, adhering to all safety standards. This expertise helps prevent installation errors that could compromise system performance. Professional installation also ensures that the system is optimized for maximum efficiency. Relying on experts can streamline the setup process and provide peace of mind.

Integration With Warehouse Management Systems (WMS)

Linking carton flow racks with a Warehouse Management System enhances inventory control. This integration provides real-time visibility into stock levels and movement. Automated data capture improves accuracy in order tracking and inventory management. WMS integration streamlines operations, from restocking to order fulfillment. This technological synergy enhances the overall efficiency and responsiveness of warehouse operations.

Maintenance And Safety Practices

Regular Inspections

Scheduled inspections are vital for maintaining system integrity and worker safety. These checks identify potential issues before they lead to system failure or accidents. Regular maintenance extends the lifespan of carton flow racks and ensures continuous operational efficiency. Inspections should focus on structural stability, roller function, and track alignment. Proactive maintenance reduces downtime and maintains a safe working environment.

Cleaning And Debris Removal

Keeping the system clean and free of debris ensures smooth operation. Regular cleaning prevents build-up that could impede the movement of goods. Clean tracks and rollers are essential for maintaining product flow and preventing damage. Establishing routine cleaning procedures maintains the system’s functionality and longevity. A clean working environment also contributes to safety and operational efficiency.

Training And Safety Protocols

Training employees on proper use and maintenance is crucial for safety and efficiency. Understanding load limits and operational procedures prevent accidents and ensure smooth operation. Safety protocols protect workers and merchandise, reducing the risk of injury and loss. Regular training updates keep staff informed about best practices and safety standards. An informed team is essential for maintaining a safe and productive warehouse environment.

Final Thoughts On Carton Flow Racks

Carton flow racks are a vital component of efficient warehouse operations. By automating stock rotation and improving access to goods, they offer significant operational benefits. These systems enhance space utilization, picking efficiency, and inventory accuracy. For businesses aiming to improve warehouse operations, carton flow racks provide a scalable and effective solution. Investing in these racks is a strategic move towards operational excellence and improved customer service.

Elevate your storage solutions with Space Maker Designs. Pallet Flow Racks provide the efficiency and scalability your business requires.

Read Also:

Elevate your storage solutions with Space Maker Designs. Pallet Flow Racks provide the efficiency and scalability your business requires.

Read Also:

- HOW TO FIND AFFORDABLE PALLET SHELVES IN DALLAS.

- 7 ESSENTIAL FACTORS TO CONSIDER WHEN BUYING PALLET RACKS IN DALLAS

- HOW TO CHOOSE THE RIGHT FORKLIFT FOR YOUR DALLAS WAREHOUSE

Frequently Asked Questions About Carton Flow Racks

Can carton flow racks be adjusted after installation?

Yes, carton flow racks can be adjusted after installation to accommodate changes in product size or volume, ensuring flexibility and scalability in warehouse operations.

Are carton flow racks suitable for all types of products?

Carton flow racks are versatile and suitable for a wide range of products, especially those requiring FIFO inventory management, though extremely heavy or oversized items may require specialized solutions.

How do carton flow racks impact order fulfillment speed?

By positioning items closer to the pick area and improving inventory visibility, carton flow racks significantly speed up order fulfillment, enhancing customer satisfaction.

Can carton flow racks be integrated with automated warehouse systems?

Yes, they are highly compatible with automated systems, including conveyors and robotic pickers, further optimizing warehouse efficiency and accuracy.

What is the lifespan of a carton flow rack system?

With proper maintenance and adherence to load specifications, carton flow racks can last many years, making them a durable investment for warehouses.

How does the cost of carton flow racks compare to traditional shelving?

Initially, carton flow racks may have a higher cost than standard shelving, but their efficiency and space-saving benefits often result in a higher return on investment over time.

Can small businesses benefit from carton flow racks?

Small businesses can leverage carton flow racks to enhance storage efficiency and order processing, making them competitive with larger operations.

Are there specific industries that benefit more from carton flow racks?

Industries with high-volume picking operations, such as e-commerce, retail, and food distribution, typically see the most significant benefits from implementing carton flow racks.

How do carton flow racks improve worker safety?

By reducing the need to reach, climb, or carry heavy loads, carton flow racks minimize the risk of workplace injuries, promoting a safer working environment.

What maintenance is required for carton flow racks?

Regular inspections, cleaning of tracks and rollers, and adherence to weight limits are essential maintenance practices to ensure the longevity and safety of carton flow racks.